Khakha Making

Khakha making is one of the traditional Indian crafts techniques. It is used to transfer the intricate embroidery design on the fabric. A perforated paper stencil also known as “Khakha” is used for this method. The term “Khakha” also known as Khaka refers to the technical or a structural drawing that is used in a textile of a fashion design. It is defined as used for the master layout or a blueprint of the design which is used to guide the artisans and printers or embroiderers during the fabric embellishment or surface ornamentation process.

Khakha is the base design plan that shows how the patterns, motifs and borders, repeats will appear on the fabric or a garment. It is one of the most important steps that is to be taken manually or even when machine-based production is required.

The Importance of Khakha in A Design:

Khakha making is one of the essential parts of textile design with product development. The use of Khakha helps to maintain the uniformity, clarity and professionalism in its execution. It is the backbone of the textile and fashion design when it comes to surface decoration. The final output includes embroidery, weaving and block printing. It ensures that every design is executed with harmony, proportion and accuracy.

The below are some importance of Khakha Making:

Accuracy:

- It acts as the technical plan where it shows the exact placement, size and spacing of the motif and patterns.

- It helps the artisan to follow the exact design and dimension.

- Helps to result in uniformity across large scale production such as embroidered fabrics and printed ones.

- You get a clear and repeatable layout with proper consistency across the fabric with proper length or batch.

Communication Bridge:

- It acts as a visual language between the designer and the craftsman.

- It ensures that the designer’s creative idea is proper translated into the final product which minimizes the miscommunication and interpretation errors.

Design Planning and Visualization:

- It helps to visualize how pattern will appear once combined with borders and motifs, also repetition techniques.

- Designers can make corrections and improvements at this stage wherever required. This saves time with wasting the material.

- A preview of final look is created which allows the adjustments in motif proportion and color planning.

Reproduction of Design:

- Khakas are stored properly for future use, and the same design can be reproduced multiple times without remaking or redrawing.

- Saves time when reproducing the design or even developing a collection using the same motifs.

- Professionally Khakha design are presented as a part of the design documentation process or even for the portfolio for the clients or even for exhibitions.

Materials and Tools Used in Khakha Making

Creating a Khakha as a technical design layout required the patience and precision with right set of materials. In India both traditionally and modern tools are used as below:

A. Drawing Base Materials

1. Butter Paper / Tracing Paper: This is widely used in India for Khakha drawings. It is smooth and semi transparent which is ideal for tracing and repeating motifs and even creating an accurate outline.

2. Gateway Paper / Ivory Sheet: It is thicker and more durable which is used to mount the final Khakha sheets and presentations and to preserve them for long time.

3. Cartridge Sheet (A3 or A2): Used to support as a base while tracing the design on butter paper. It heals to avoid tearing and keep the drawings flat.

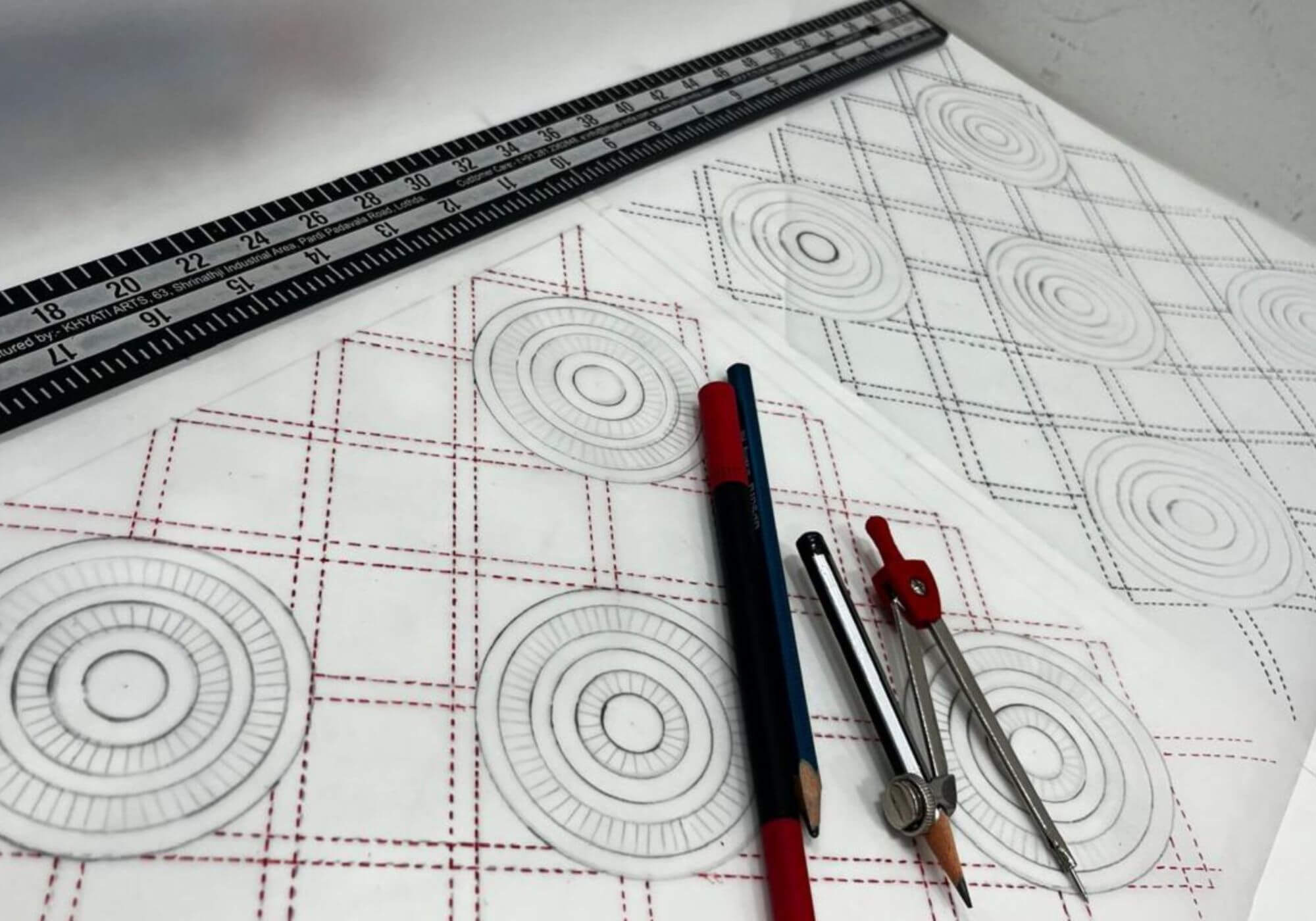

B. Drawing and Drafting Tools

1. Pencils with grades such as 2H, H, HB for fine guidelines for sketching motifs and darker outlines are used before inking. Mechanical pencil is used for the consistency of the line thickness for detailed designs.

2. Geometry Sets are needed for the circular and symmetrical motifs and design placements.

3. Rulers for marking borders and margins with accurate repeat of measurements.

C. Inking and Outlining Tools/ Coloring:

1. Black Fine Liner Pens are used to create the final outlines such as Micron Pens in India.

2. Rotring Ink Pens can be used for the professional Khakha drawing and permanent lines.

3. Black Indian Ink or Waterproof drawing ink can be used occasionally for the decorative detailing or shading.

4. Watercolours, poster colors, sketch pens or other mediums can be used to show color on the motifs that will help you differentiation to motifs and borders.

D. Supporting and Measuring Tools

1. Masking Tape or Paper Tape is used to fix the butter paper on the drawing board to prevent the movement while working.

2. Drawing Board or Wooden Board for the flat and firm surface.

3. Drafting Pins and Clips to hold the papers securely when you are working on the large sheets.

4. Tracking Light Box can be used optional when you trace some complex repeats or the symmetrical motifs at ease.

Traditional Indian Tools (Used in Artisan Workshops)

1. Oiled Paper / Handmade Tracing Sheets – This is used in traditional block printing in the areas of Jaipur, in Bagru and Ajrakh to transfer the patterns.

2. Chapai Powder: It is grounded fine powder used by the craftsmen to mark designs on the fabric from the Khakha outlines. Charcoal or Sindhoor powder, Indigo powder can also be used for the marking. Kerosene is mixed with it for the tracing. Chalk powder, zinc oxide or talcum can also be used.

3. Khakha Pen / Chapai Pens: It is a pen like tool or a wooden stick in a fine muslin cloth tip used to trace the design. This helps to pounce the needle into the Khakha creating holes. Now the electric Khakha pens are available to create the perforated design.

4. Kerosene lamps or the Backlit Tables: Instead of light boxes electric these are the traditional tracking method used.

5. Wooden Khakha Frames: These can be used in block printing to secure the tracking sheets.

6. Cotton Pads or Muslin Dabber are used to apply the powder over the perforated design.

TRADITIONAL NAMES OF THE MATERIALS:

| Khakha Sheet | “Khakha” or “Design Sheet” |

| Chapai Powder | “Chapai” or “Neel Chapai” |

| Khakha Pen / Chapai Pen | Kalam” or “Khakha Kalam” |

| Perforation Needle / Pouncing Tool | “Sui” or “Needle Wheel” |

| Cotton Pad / Muslin Dabber | “Patti” or “Pouch” |

| Fabric Base | “Kaam Ka Kapda” |

Labelling and Documentation of Materials:

It is necessary to label the design number, title and date. Stickers and paper labels are used for the project sheet labelling. Transparent sheets and plastic folders are used for protecting and storing the Khakha sheets for the safety from dust and design getting smudges.

Types of Khakha

Khakha is not the one size that fits all drawing, and it also depends upon the type and layout of depend upon the purpose of drawing. Designers and artisans in India use various Khakha techniques and formats as below:

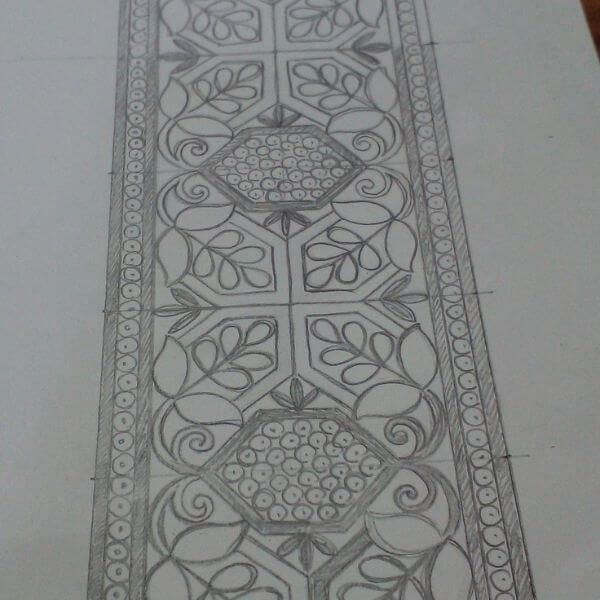

Motif Khakha:

This focuses on one single motif or the design motif such as flower, leaf, any geometric shape, paisley and more. It helps to show in detail design of the motif which may include line shape and other stitch indications. This can be used for creating a block design for printing or an embroidery motif or even repeat design development for manual as well as digital layout.

Layout Khakha:

A Khakha in the form of a layout helps to arrange the design on a fabric or even a garment piece that includes the placement of the motifs, panels, pallus of saree or dupattas or even the borders. It helps to visualize the appearance of the design when it is executed. Gives a proper composition and proportion. This is used for saree, shawl, dupatta layouts on wide bases.

Border Khakha:

It only focuses on the border portion of a fabric or a saree. The border Khakha are normally long and narrow designs that run along the edges of the fabric. They are great for the planning of the edges of saree, stoles, dupattas, home furnishings, curtains and bedspreads. Ensures the uniform width and continuous pattern flow.

All Over Design Khakha:

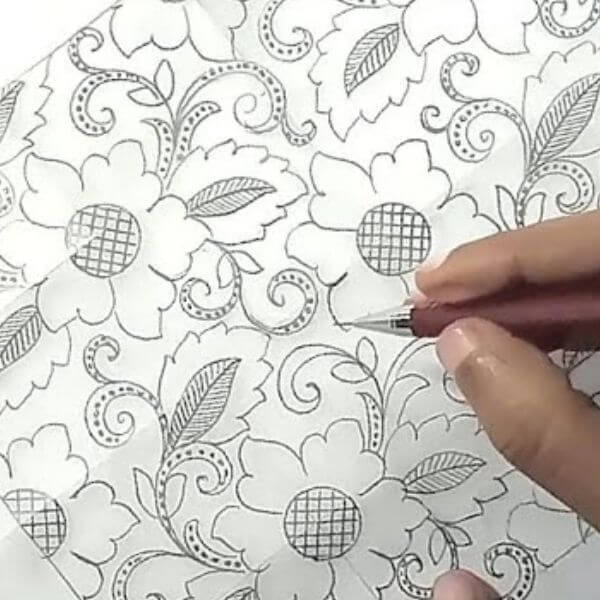

This is also called as Jaal Design which displays the motifs continuously all over the fabric specifically in 8 x8 inch section and shows how the motifs are connected and repeated horizontally and vertically. Mostly used in prints and embroideries. Fabrics used can be the yardage or kurtas or even bed linens.

Corner Khakha

Corner Khakha is made where two borders align such as corners of fabric, dupatta or saree Palu. This type of Khakha helps to ensure the motifs are aligned correctly at the junction without any distortion. Designed for tablecloths, bedcovers, pillow covers or mats.

Embroider Stitch Khakha

This type od Khakha includes some notation or symbols that are different embroidery stitches such satin or chain or also for the Aari work or zardozi work. It helps the artisans to understand the technical map. Used for the hand or even machine embroidery. It guides the placement of thread colors, sequins and beads.

Example symbols:

- — small dash = chain stitch

- • dot = French knot / bead

- //// diagonal shading = satin stitch

- X = sequin placement

Step-by-Step Process of Khakha Making and Chapai Technique:

Step-1- Preparation (Before you design):

- Define the purpose such as Khakha Design used from printing, embroidery or weaving or fabric painting.

- What is your product? (Saree, Dress, Dupatta, Upholstery etc,)

- Check out the fabric width and usable repeat.

- Decision of the stitch technique in case of embroidery or colourway.

- Set up your workspace with the help of flat board, tape and proper light with the required tools.

Step-2- Prepare the Khakha Sheet

- Start with your design using proper tools, measuring the proportion and checking the repetition of the design on the A3 sheet or the Butter Paper.

- Apply the technical notation and label wherever needed.

- Once the design is finalised use thick pens to finalise the designs and colors for the notation on the final design paper that is the KHAKHA SHEET.

- Once this is done perforate the final sheet along all design lines using a Khakha Pen or fine needle. Make sure the holes are evenly spaced. The perforation will allow the Chapai powder to pass through the design and mark on the fabric.

Step-3- Transferring the Design on Fabric:

- Spread the fabric on a flat surface or embroidery frame and fix it properly using the pins to avoid the shifting. Use different fabrics or muslin under the main fabric to avoid getting damage.

- Now place the Khakha on the fabric, align the perforated Khakha sheet on the exact fabric where you need the design to be placed. Use a masking tape or pins to keep the Khakha steady.

- Use a Chapai Powder with a muslin pouch dipped in the Chapai either powder or liquid form and dab gently over the perforated lines and trace the design properly. For dark fabric use white Chapai powder and for the light fabrics used the blue or black Chapai mix for the visibility.

- Move gently and evenly, do not over press. Dry Chapai powder can be used for the delicate fabrics such as silk. Wet Chapai is used for the heavier fabrics.

Step-4- Lift and Inspect the Fabric:

Slowly lift the Khakha paper without smudging. The design will now appear in fine dotted line on the fabric surface. If any space is faint, you can repeat the same procedure gently. You may use a water spray lightly to fix the powder.

In this way your Khakha gets transferred over the fabric and then the actual work begins. Once the design is transferred the artisans start the work and gradually the powder starts disappearing or washed away after the completion of the work.